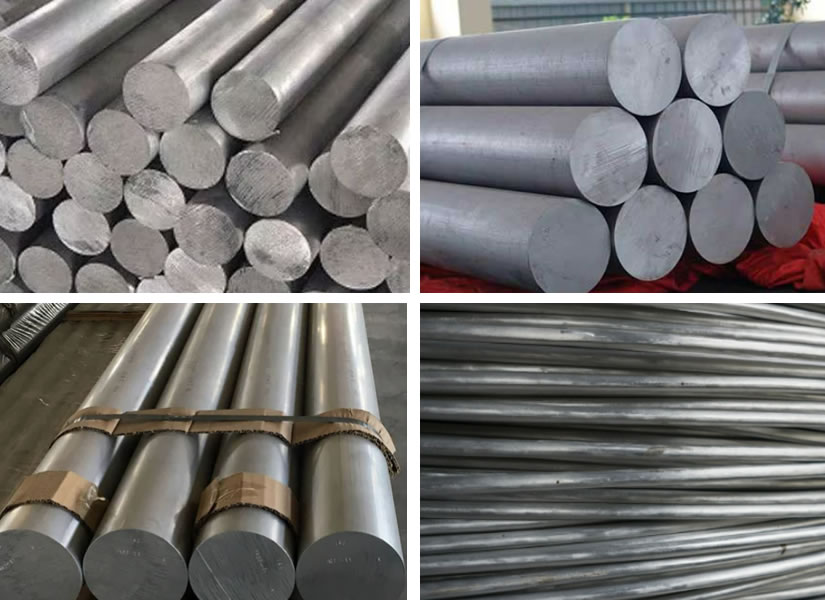

Aluminum rods

7075 aluminum is a kind of cold treatment forging alloy with high strength and hardness, far better than mild steel. 7075 aluminum is one of the most powerful commercial alloys. It has common corrosion resistance, good mechanical properties and anodic reaction. The fine grain makes the deep drilling performance better, the tool wear resistance enhanced, the thread rolling more different, the density requirement is smaller, the hardness requirement is higher.

7075 alloy belongs to Al Zn mg Cu super hard aluminum. It has been used in aircraft manufacturing industry since the late 1940s and is still widely used in aviation industry. It is characterized by good plasticity after solution treatment, especially good heat treatment strengthening effect, high strength below 150 ℃ and especially good low temperature strength; The welding performance is poor; There is a tendency of stress corrosion cracking; It needs to be protected by aluminum coating or other treatment. Two stage aging can improve the stress corrosion cracking resistance of the alloy. The results show that the plasticity of the annealed and quenched sheet is slightly lower than that of 2A12 and better than 7A04. The static fatigue, notch sensitivity and stress corrosion resistance of the sheet are better than those of 7A04. Among them, 7075-T651 is the best product in aluminum alloy with high strength and far better than soft steel. The alloy has good mechanical properties and anodic reaction, and is a typical aluminum alloy material for aerospace and military industry.

| Product | Alloy Series | Alloy | Temper | Diamater (mm) | Length (mm) | END USE |

| ALUMINUM BAR /FLAT BAR /ROD/Round Rod | 1xxx | 1050, 1100 | H112 | 5-650mm | 500-6000 | ships, automotive and aircraft board weldable parts; pressure vessels, refrigeration units, TV towers requiring rigorous fire protection Equipment, transportation equipment, missile parts, armor and so on. |

| 5xxx | 5083, 5086, 5754, 5182 | O, H112 |

| 6xxx | 6061, 6082 ,6063 | T6 , T651 |

| 7XXX | 7050, 7075 | O, T6、T652、T6511 |

| 2XXX | 2024 ,2219 ,2011 . |

|

Main Applications for 7075 Aluminium

Aerospace industry, blow molding (bottle) mold, ultrasonic plastic welding mold, golf head, shoe mold, paper plastic mold, foaming mold, dewaxing mold, template, fixture, mechanical equipment, mold processing, used to make high-end aluminum alloy bicycle frame.

7075 status: O, T6, T73, T76 plate.

7075 status: O, t651, t7351, t7651 thick material

7075 status: O, T6, t173 stretch tube

7075 status: O, T6, t6510, t6511, T73, t73510, t73511, T76, t76510, t76511 extruded tube, shape, rod and wire

7075 status: O, H13, T6, t651, T73, t7351 rolled or cold worked bar

7075 status: O, H13, T6, T73 cold worked wire rod

7075 status: T6, T73 rivet wire

7075 status: F, T6, t652, T73, t7352 forgings

Characteristic for 7075

1. High strength heat treatable alloy.

2. Good mechanical properties.

3. Good usability.

4. Easy processing and good wear resistance.

5. Good corrosion resistance and oxidation resistance.

7075 is an aluminum alloy with zinc as the main alloying element, but sometimes a small amount of magnesium and copper are added. Among them, super hard aluminum alloy is a kind of alloy containing zinc, lead, magnesium and copper, which is close to the hardness of steel and can be strengthened by heat treatment. It is a high strength and heat treatable alloy with ordinary corrosion resistance and good mechanical properties. Aluminum 7075 is a cold treatment forging alloy with high strength, far better than mild steel. 7075 aluminum alloy is one of the most powerful commercial alloys. General corrosion resistance, good mechanical properties and anodic reaction. The fine grain makes the deep drilling performance better, the tool wear resistance enhanced, and the thread rolling is more different from the heavy one.

heat treatment

Zinc is the main alloying element in 7075. Adding magnesium to the alloy containing 3% - 7.5% zinc can form mgzn2 with remarkable strengthening effect, which makes the heat treatment effect of the alloy far better than that of Al Zn binary alloy.

With the increase of Zn and Mg content in the alloy, the tensile strength will be further improved, but the resistance to stress corrosion and exfoliation corrosion will be decreased.

After heat treatment, very high strength characteristics can be achieved. 7075 materials are generally added with a small amount of copper, chromium and other alloys. Among them, 7075t651 aluminum alloy is particularly high-grade. It is known as the best aluminum alloy product with high strength and far better than any mild steel.

TAGS:aluminium supplie,aluminium rods manufacturer,aluminum rods supplier,aluminum rods manufacturer,5083 aluminum,5754 aluminum,5052 aluminum,5182 aluminum,6061 aluminum,7075 aluminum,2024 aluminum,3003 aluminum,2024 aluminum

FAQ

Q: Are you a trading company or manufacturer?

A: We are a factory.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge

Q: What are your terms of payment?

A: We accept T/T, LC, Western Union, Paypal , Alibaba Credit Insurance Order, etc. The payment method can be negotiated by both parties according to the actual situation.

OUR EXHIBITION

PACKING & DELIVERY

CONTACT US

Quzhou Aoyin Metal Materials Co. Ltd

ADDRESS:339-1 Kecheng District,Quzhou City,Zhejiang Province,China

Phone:0086-0570 386 9925

Email:info@aymetals.com

Whatsapp/Wechat:0086+13305709557