What Thickness of Aluminum Plate Is Used for Silos?

Choosing the right aluminum plate thickness is one of the most critical decisions in aluminum silo design.

Plate thickness directly affects structural safety, service life, and long-term operating costs—especially for aluminum silos used for grain and bulk material storage.

This article explains how aluminum plate thickness is determined for silos, what factors influence the selection, and which aluminum alloys are best suited for silo applications.

Why Aluminum Plate Thickness Matters in Aluminum Silo Design

An aluminum silo is a typical thin-walled cylindrical structure.

Its wall plates must safely withstand:

Continuous material pressure

Wind and environmental loads

Long-term cyclic loading during filling and unloading

Research on vertical silos shows that storage conditions have a significant impact on structural behavior. Compared with empty silos, fully loaded silos experience much higher structural demands, making full-load conditions the most critical design case.

This means aluminum plate thickness should never be selected based on empty or partial-load conditions, but must be designed for the worst-case full-load scenario.

Key Factors That Determine Aluminum Plate Thickness for Silos

There is no single “standard thickness” for all aluminum silos. Instead, thickness is determined by several interrelated factors.

1. Silo Diameter and Height

As silo diameter and height increase, the lateral pressure acting on the silo wall increases significantly.

Larger silos generally require thicker aluminum plates to maintain structural stability and prevent deformation.

2. Stored Material Properties

Different materials impose different loads on silo walls.

Key material parameters include:

Bulk density

Internal friction angle

Flow behavior

Grain, feed, and bulk powders generate varying lateral pressures, directly influencing the required plate thickness.

3. Storage Conditions: Empty vs Full Load

Engineering studies confirm that structural response changes dramatically under different storage conditions.

Fully loaded silos represent the most demanding case, and aluminum plate thickness must be selected accordingly to ensure safety throughout the silo’s service life.

4. Environmental Loads

Wind load, temperature variation, and corrosion exposure also affect thickness selection, especially for outdoor aluminum silos operating in coastal or humid environments.

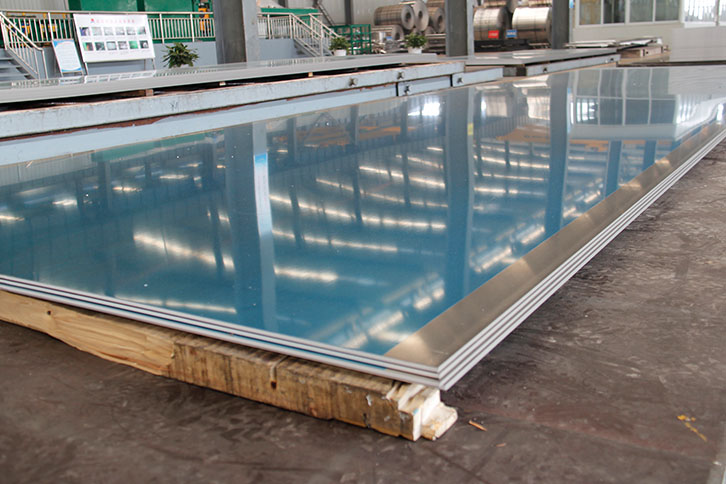

Mechanical Properties of Aluminum Plates Used for Silos

When selecting aluminum plates for silo construction, material performance is just as important as thickness.

Key aluminum alloy properties include:

Strength and Yield Strength

Adequate yield strength ensures the silo wall can resist material pressure without permanent deformation.

Elastic Modulus

Although aluminum has a lower elastic modulus than steel, proper thickness design and structural optimization ensure sufficient stiffness for silo applications.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion—especially important for grain and bulk material storage.

Common Aluminum Alloys Used in Aluminum Silos

Based on industry practice, the most commonly used aluminum alloys for silo panels include:

3003 aluminum plate (width up th 2650mm)

Good formability

Excellent corrosion resistance

Widely used for small to medium silos

5754/5083 aluminum plate (thickness 4-25mm)

Higher strength

Excellent corrosion resistance

Suitable for large aluminum silos and demanding environments

These alloys offer an excellent balance between strength, durability, and long-term performance.

Typical Aluminum Plate Thickness Ranges for Silos (Industry Experience)

From industry standards and engineering practice, aluminum plate thickness for silos typically falls within the following ranges:

Small aluminum silos: approximately 3-6 mm

Medium aluminum silos: approximately 4-8 mm

Large aluminum silos: approximately 6-10 mm

The final thickness should always be confirmed based on:

Silo dimensions

Stored material

Design standards

Safety factors

This is why professional suppliers usually provide project-based thickness recommendations rather than fixed values.

Aluminum Silos vs Steel Silos: Why Aluminum Performs Better

Compared with traditional steel silos, aluminum silos offer several advantages:

Lightweight but Strong

Aluminum has a high strength-to-weight ratio, reducing overall structural weight while maintaining safety.

Superior Corrosion Resistance

Unlike steel, aluminum does not require heavy anti-corrosion coatings, lowering long-term maintenance costs.

Longer Service Life

Aluminum silos maintain stable performance over decades, even in harsh environments.

Easier Installation

Reduced weight simplifies transportation and on-site installation.

Choosing the Right Aluminum Plate Supplier for Silo Projects

Selecting the correct aluminum plate thickness is a technical decision, not just a pricing issue.

A reliable aluminum plate supplier should offer:

Engineering support for thickness selection

Stable alloy quality

Custom plate sizes and thicknesses

Consistent mechanical performance

As an experienced aluminum plate supplier, we provide high-quality aluminum plates specifically designed for aluminum silo applications, supporting projects from material selection to final installation.

Conclusion

So, what thickness of aluminum plate is used for silos?

The answer depends on silo size, stored material, loading conditions, and alloy selection.

By combining proper thickness design with the right aluminum alloy, aluminum silos deliver outstanding safety, durability, and long-term value—making aluminum plates an ideal material choice for modern silo construction.

If you are planning an aluminum silo project, feel free to contact us for professional material recommendations and technical support

.